O-ring Slot Design Calculator

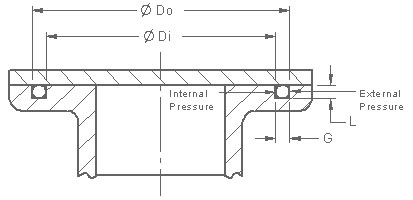

Metric o-ring groove designs vary greatly and choosing the right one for your application is important for maximum o-ring performance. This metric o-ring groove design reference guide will help you find the right radius, back-up, pressure and other o-ring dimensions for basic applications. The O-ring calculator tool is intended to form the basis of an o-ring installation, and assist with selection of o-ring and hardware dimensions. Recommendations are based on available technical information, and are offered as suggestions only, any reliance placed on such information by the user is strictly at the user’s risk. Gland Depth x Groove Width (area of the gland) must be larger than the cross section area of the o-ring. Otherwise many bad things will happen to your design. L = Gland Depth L = Groove Depth + Clearance. Designing the parts of an application where o-rings will be applied is broadly termed “o-ring groove design”. In order to seal properly, the o-ring has to deform in the application by being compressed and stretched in any number of ways. The design of the groove where the o-ring sits plays a major role in how the o-ring performs its sealing.

- O-ring Slot Design Calculator Download

- O-ring Slot Design Calculator Formula

- O-ring Slot Design Calculator Software

- O-ring Slot Design Calculator Estimate

- O Ring Dovetail Groove Design Calculator

- O-ring Slot Design Calculator Square

Of the four characteristics that define an o-ring (material, durometer, color, and size), determining and properly communicating the exact size needed is often the trickiest part of an order. Applying tried and true methods for determining the correct size will save you time in the short-term and frustration and additional cost down the road. Read on to learn how to properly size an o-ring the first time around.

How to Measure O-Ring CS and ID

The best way to size an o-ring is by measuring the CS (cross-section) and ID (inside diameter). For measuring the cross-section, it is best to use a caliper, a.k.a. micrometer. If you don’t have one available, various other sizing tools can be used to get a close estimate.

When measuring very small IDs, it is also best to use a caliper. For larger IDs (over 6 inches), it is best to use an O-Sizer or Pi-Tape.

Once the CS and ID of the o-ring are determined, you can use our AS568 O-Ring Size Chart to determine if these dimensions correspond to one of the “standard” sizes.

Shop For O-RingsO-ring Slot Design Calculator Download

Metric vs Standard O-Ring Sizes and Tolerances

All o-rings can be described by either metric (mm) or standard (inch) dimensions. However, if the o-ring matches an AS568 size, that’s the best way to reference it since this is the most common standard here in the USA. If not, you may be able to find a “metric” o-ring that matches the dimensions you need.

O-ring Slot Design Calculator Formula

One important thing to consider when sizing o-rings is tolerances. Due to manufacturing limitations, there will always be some variance in the dimensions of o-rings. These variances are called tolerances, and the standard acceptable tolerances are specified in the previously mentioned AS568 O-Ring Size Chart or the Metric Tolerances Chart for Metric O-rings. As an example, for any of the AS568 100 Series o-rings, the cross-section is .103” with a tolerance of ± .003”. This means the cross-section could measure as small as .100” or as large as .106”.

O-Ring Standard (AS568) Sizes

If the CS is one of the standard AS568 sizes such as .070, .103, .139, .210, or .275 inches, then you probably have a standard-sized o-ring. Measure its ID, and look it up on a size chart. If the ID is listed on the chart (or within tolerance), you have a standard size. Look up the 3-digit “dash” # and that will be your o-ring size.

Metric O-Ring Sizes

If the CS of the o-ring is not one of the standard AS568 sizes, then you may have a “metric” o-ring. In this case, simply measure the CS and the ID as discussed above to identify the size needed on our metric size chart. At Global O-Ring, we identify metric sizes by their CS X ID in the format #.##X###. So for example, a 1 mm CS X 5 mm ID o-ring would be 1.00X005.

Various Tools to Size an O-Ring & Best Applications

It may be tempting to use a ruler or tape measure, but these will not give you the detailed measurements you need. Instead, we recommend the following tools (all available in the Global O-Ring and Seal store) to size o-rings:

- Laminated Size Chart for AS568 Sizes – Stop here to get our easy to use flip chart featuring the silhouettes of 239 different sizes of o-rings.

- Molded Sizing Cone – Place your o-ring on this cone to see if it is the same size as one of our 184 most popular sizes.

- Sizing Gauge – This sliding gauge can measure the inside diameter of an o-ring up to 13 inches.

- Calipers – A preferred tool for precise measurement, this sliding tool can measure the diameter and length of many components, including o-rings. Most calipers will only extend 6 inches, and a different tool is needed for those larger than 6” IDs.

- O-Sizer – This specially designed o-ring measuring tape comes in three different sizes and is used to measure the ID of metric and AS568 o-rings up to 26”.

- Pi-Tape – The most precise tool to measure the inside diameter of an o-ring. Pi-Tapes are metal precision-engineered tapes designed for the specific purpose of measuring the ID of a round object. Each Pi Tape will measure to the thousandths of an inch (.001”). There are various size options depending on the ID you need to measure, but the most common sizes are 2-12”, 12-24”, 24-36”, 36-48”, and 48-60”.

Global O-Ring and Seal’s Sizes Selection for O-Rings

Global O-Ring and Seal carries a full line of o-rings in all standard AS568 and most metric sizes. We are also here to guide you through the sizing process. Give us a call at 832-448-5550 to speak with an Industry Expert, or if you are local to the Houston area, come visit us at our Will Call department for more help on sizing o-rings.

O-ring Slot Design Calculator Software

Shop For O-RingsTwo things are equally important for the reliable performance of an O-ring seal: the right size and the right material. Parker’s new O-Ring Selector is an engineering design tool that enables users to make the right material and size selections easily, quickly and reliably – in a single application. This post explains how to design the sealing system using the “Size Selector.”

O-ring Slot Design Calculator Estimate

See also related blog posts:

Precise calculation of installation conditions: fast and easy with the “Size Selector”

The “Size Selector” calculates the installation conditions and the suitable O-ring. It is divided into three segments: “Hardware Configuration,” “Sizing Selection” and “Results” (of the calculation).

Description of the system to be sealed

The “Hardware Configuration” segment is used for a detailed description of the sealing system. The user can choose between two radial (Piston und Rod Seal) and two axial (Internal and External Pressure) sealing systems. Subsequently, these choices can be specified in greater detail by selecting liquid systems or gas/vacuum systems. The selection of the various options is intuitive due to the clear, graphic presentation of the individual sealing systems.

O Ring Dovetail Groove Design Calculator

“Hardware Configuration” also includes a look at the diverse thermal expansion coefficients of the hardware components. Representative values, e.g. for steel or aluminum, are available here. Of course, if known precisely, these values may also be entered manually to parameterize the sealing system with maximum accuracy. Chemical swelling of the seal itself may be included in the calculation as well.

Calculation of the sealing system

The “Sizing Selection” segment is focused on the comprehensive calculation of the system to be sealed. If known, all values such as O-ring diameter, piston diameter, etc. can be entered manually. Alternatively – if complete information is not available – an automatic parameterization of the sealing system can be performed via the selection of the O-ring diameter and (for instance) the targeted piston diameter. All the individual values calculated this way can be adjusted manually in a second step and their effects on the functionality of the sealing system reviewed. The toleration of the hardware components can be adjusted to the user’s application as well to satisfy the various quality requirements in the manufacturing process.

Review of results

The “Results” segment displays the calculated results in a structured manner. For the key results parameters, the recommendations are shown according to ISO/Parker specifications. In addition, minimum and maximum tolerations for the results parameters are indicated. A simple visual check if the calculated sealing system corresponds to ISO/Parker recommendations is made using color codes: green stands for “Recommended,” yellow for “Warning” and red for “Critical.”

Users can enter their own comments on the calculations made in “Notes.” After the review of the sealing system has been completed, the data obtained can be converted into a PDF.

>>> Start imperial version

>>> Start metric version

Additional information:

Article contributed by Dr. Heinz-Christian Rost

Technology & Innovation Manager

Engineered Materials Group Europe, Prädifa Technology Division

O-ring Slot Design Calculator Square

Related, helpful content for you: